IF WE DON'T HAVE IT ARE YOU SURE YOU NEED IT?.

H7000 SERIES DISCBINE

Even in tough conditions, Discbine® disc mower-conditioners quickly turn heavy crop into fast-drying windrows or wide swaths. They slice through thick, down and tangled, wet crops and cut through fire ant hills and gopher mounds like they are not even there. New Holland’s extensive line of Discbine disc mower-conditioners gives you plenty of choices. From the economical seven-disc models with a modest, nine-foot cut up to the highly productive 12-disc models that quickly mow down 15’ 7” in every pass, there’s a model that matches your acreage and operation.

MOWMAX™ CUTTERBAR ADVANTAGE

Discbine disc mower-conditioners feature the latest advances in cutterbar technology: the MowMax™ true modular cutterbar with ShockPRO™ disc drive hubs. If you hit a foreign object in the field, the ShockPRO hub absorbs the shock of the impact before damage to drive components occurs. Best of all, the cutterbar is covered by three-year MowMax™ protection.

A CHOICE OF CONDITIONING SYSTEMS FOR FAST DRYING

You’ll harvest crops more quickly and produce more nutritious, high-value feed thanks to New Holland conditioning systems. Choose the gentle conditioning of rubber chevron-intermeshing rolls that save the delicate leaves, steel chevron-intermeshing rolls for winter forage or longstem and cane grasses, or New Holland's LeaningEdge™ flail conditioning system for fast drying of grass hay.

YOUR CHOICE OF TONGUE DESIGNS

Flexible side-pull Discbine models are available with economical straight- and bent-tongue configurations with a standard drawbar or a bent tongue with optional swivel hitches for easier cornering and improved maneuverability. The versatile, center-pivot Discbine models let you cut at any angle—to either side or directly behind the tractor— with outstanding maneuverability while cutting and transporting.

THE TOUGHER THE CONDITIONS, THE BETTER DISCBINE® PERFORMS

AT A GLANCE: Model No. of discs Cutting width Conditioning system

H7220 7 9’2” Rubber rolls

H7320 7 9’2” LeaningEdge™ Flails

H7230 8 10’4” Rubber or Steel rolls

H7330 8 10’4” LeaningEdge™ Flails

H7450 10 13’ Rubber or Steel rolls

H7550 10 13’ LeaningEdge™ Flails

H7460 12 15’7” Rubber or Steel rolls

H7560 12 15’7” LeaningEdge™ Flails

3-YEAR MOWMAX PROTECTION

New Holland’s MowMax™ cutterbar sets the industry standard. It’s the secret to smooth, quiet, trouble-free mowing— and fast, inexpensive cutterbar servicing. Driven through individually sealed gearboxes with dedicated oil reservoirs, discs are never at risk for oil starvation, even while cutting on side hills and inclines. Don’t worry about costly repairs. If the mower hits an obstruction in the field, the damage to a module is isolated and fully contained minimizing risk to the other modules.

CLEANER MOWMAX CUTTING

CLEANER MOWMAX CUTTING

The MowMax cutterbar features new, lower-profile-design rock guards to allow closer cutting at a flatter cutting angle. This design allows the cutterbar to run more lightly on the ground for less wear, less damage and a more consistent cut height. Adjustable header flotation springs and on-the-go cutting height adjustment allow you to get all of your valuable crop without scalping or knife damage.

SHOCKPRO™ PROTECTION

MowMax cutterbars are equipped with the added protection of ShockPRO™ disc drive hubs. The ShockPRO hubs absorb the impact before damage to drive components can occur and are quick to replace in the field so you can keep harvesting when the weather is right.

3-YEAR MOWMAX™ PROTECTION

You not only get the best disc cutting performance in the business, you get the peace of mind of 36 months of protection coverage. That’s two years of additional protection on the MowMax cutterbar after the base one-year warranty on the full machine. It’s a New Holland exclusive.

DISCBINE® DISC MOWER-CONDITIONERS

ADVANCED MOWMAX™ TRUE MODULAR DISC CUTTERBAR TECHNOLOGY

The New Holland ShockPRO™ hub heads off potential damage to gears and module drive shafts. It saves you hassle, time, and repair costs

The New Holland Discbine design ensures long life and maximum capacity, even in the toughest conditions:

• To withstand punishing conditions, austempered ductile steel discs provide extra hardness, toughness and durability.

• To avoid disc and knife damage in rocky fields, simply adjust the cutting angle hydraulically from the tractor cab (not standard on the H7220/H7320).

• For maximum durability, rock guards are made of ductile iron, not stamped sheet metal like some units.

• For optimum flotation and protection of the crop stubble, skid shoes are 8-inches wide and extend behind the module a full two inches. Pairs of counter-rotating discs spin at 3,000 rpm for fast, clean cutting without plugging. The Discbine header is suspended independently from the trail frame, allowing it to closely follow changing ground contours and reducing stubble damage and skid shoe wear.

REPLACEMENT KNIVES TO MATCH FIELD CONDITIONS

Choose from four replacement knives to match your field conditions. All feature two cutting edges for double the life. Simply flip over the knives when the front edge dulls. Plus, you easily change the knives from the front—no need to reach from the back of the cutterbar.

• 14° smooth knives for extra lift and clean cutting (standard)

• 14° serrated knives extend wear life in abrasive conditions

• 7° smooth knives cut clean with less ash content in the hay

• Rock knives for more durability in rocky or stony conditions Rock 7° 14°

DISCBINE® DISC MOWER-CONDITIONERS

CHOICE OF ROLL OR FLAIL CONDITIONING

New Holland's offers a wide selection of conditioning systems to help you beat the weather and produce nutritious, high-quality feed that improves animal production.

CHEVRON STEEL INTERMESHING ROLLS:

Durable chevron steel intermeshing rolls are designed for use with all crops, but show a real advantage in cane-type crops, grain forage crops and extra-tall grass crops. The chevron pattern of the steel lugs provides aggressive full stem crimping, smooth crop flow, and even distribution into fast drying swaths or windrows. Rugged all-steel roll construction resists wear better than rubber, providing a long life even in highly abrasive conditions.

TORSION-BAR ROLL-PRESSURE SYSTEM

Year after year, New Holland’s torsion-bar roll-pressure system has proven to be the most effective design for delivering consistent, thorough conditioning. The no-tools-required hand crank makes it easy to tailor roll pressure to the crop without crawling under the machine with wrenches. The unique, over-center linkage momentarily relieves roll pressure, allowing crop slugs or foreign objects to pass without plugging for non-stop mowing.

CHEVRON RUBBER INTERMESHING ROLLS

Gentle chevron rubber intermeshing rolls provide full stem crimping and cracking with a scrubbing action while handling high-feed-value leaves delicately, making it the ultimate solution for alfalfa and clover. This is possible because of the large 10.4-inch roll diameter, the rubber compound, the intermeshing fit and profile of the lugs. These features work together to grip the crop and generate an even flow crop through the rolls to provide an even spread into fast drying swaths or windrows.

Torsion-bar roll-pressure system

Chevron Rubber Rolls

90

80

70

60

50

40

30

20

10

[Source: University of Wisconsin-Extension, Arlington, WI, July 30 and 31, 2007]

FLAIL CONDITIONING FOR GRASS CROPS

The New Holland LeaningEdge™ flail design delivers more effective conditioning of grass crops for fast drying. The 20-degree tangent of LeaningEdge™ flails causes more outward pressure, pushing crop against the adjustable hood for more aggressive conditioning, and releasing at the ideal moment to prevent carry-around for uniform, fast-drying swaths or windrows. For delicate conditioning of legumes and grass mixtures, raise the hood position for more gentle handling. Or, for maximum conditioning, increase flail rotor speed and add the dimpled hood liner.

FROM SWATH TO WINDROW, FAST AND EASY

All Discbine® models feature fast and easy windrow shield and swathgate adjustments, without tools, so you can quickly adjust to crop and moisture conditions and your harvesting method. Spread the cut crop in a fast-drying swath or into a tight, three-foot-wide windrow that’s ready to bale or chop.

WIDE AND THIN CROP SPREADING SPEEDS DRYING

The wide and thin crop-spreading deflector kit spreads crop to the full width of cut, exposing more crop to the sun and providing faster drydown. University tests confirm that the more leaves are exposed to the sun, the faster crops dry and the more feed value is retained. Quick drying reduces sun bleaching and gives you an advantage when you need to beat the weather and bale or chop before the rain. The kit is fitted to the swathgate with the windrow shields removed. Visit your New Holland dealer for complete details.

EFFECT OF WIDE SWATH VS NARROW SWATH DRYING RATE.

LeaningEdge™ Flail DISCBINE® DISC MOWER-CONDITIONERS TURN A NEW CORNER WITH DISCBINE® PRODUCTIVITY

Maneuverability has always been a given with Discbine® disc mower-conditioner. You can turn, pivot and cut clean around tight corners to mow more acres every day. From the agile seven-disc models to the largest 12-disc models, Discbine disc mower-conditioners provide you with outstanding control and maneuverability that reduces fatigue and improves productivity.

H7220 AND H7320 – SIDE-PULL (Standard Straight Tongue)

The 9’2” cutting width and narrow transport of the side-pull H7220 and H7320 models makes them ideal for mowing tight spaces and accessing smaller farm gates. The 540-rpm drive and low power requirement means you can mow and condition your crop for fast drying with as little as 65 PTO horsepower.

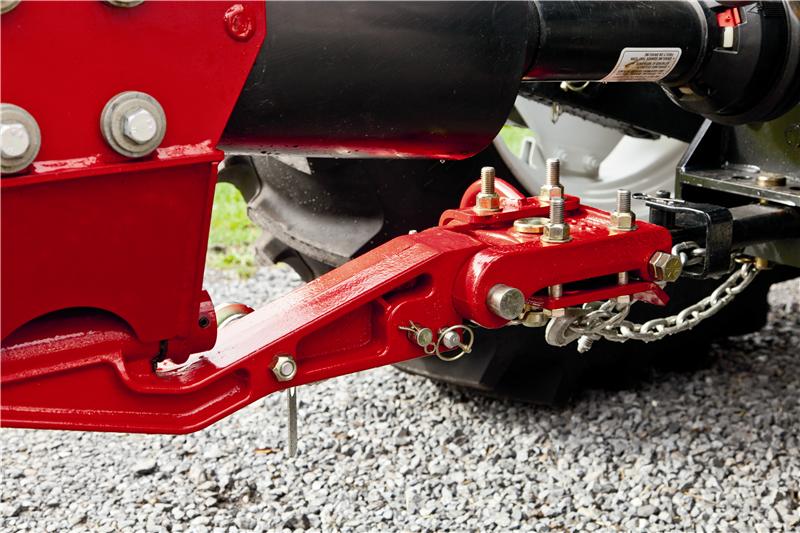

H7230 AND H7330 – SIDE-PULL (Standard Bent Tongue)

The unique New Holland bent-tongue design provides extra tire clearance for tighter turns to the right, providing outstanding maneuverability in small or oddly shaped fields. The wider 10'4'' cutting width cuts more acres per hour and is well suited to tractors with just 80 PTO horsepower. The standard hitch offers simple drawbar attachment and the choice of 540- or 1000-rpm drive, a constant velocity PTO that allows you to cut square corners without PTO vibration or noise.

H7230 AND H7330 – SIDE-PULL (Optional Swivel Hitch Tongue)

For maximum productivity both in the field and on the road—add the new swivel hitch option. It couples the advantages of the standard bent tongue design with the extreme maneuverability of a swivel hitch. Turn beyond 90° to the right for smooth clean cutting around tight corners. The swivel gearbox maintains the PTO angle straight through the turn eliminating constant velocity joints and extending driveline life and reliability. Both the two-point and drawbar swivel designs maneuver easily when transporting and attach quickly to your tractor. The drawbar swivel uses a slip-fit drawbar extension that uncouples easily. Simply remove the pin so your tractor is ready for other jobs. There’s no need to rigidly bolt, then unbolt, the extension on the drawbar. Two-point attachment eliminates the hitch pin and provides added clearance over large windrows.

H7450, H7550, H7460 and H7560 CENTER-PIVOT

The center-pivot tongue design allows the tongue to swing 38.5° to the right or left so you can cut on either side or directly behind the tractor and mow around obstacles—even on slopes—to get all the crop. The outstanding center-pivot, turn-and-go maneuverability allows rapid headland cycle times and provides straight windrows or swaths to improve your harvesting productivity.

H7450 AND H7550 CENTER-PIVOT (Optional Swivel Hitch)

H7460 AND H7560 CENTER-PIVOT (Standard Swivel Hitch)

For making turns greater than 90°, tight headland turns, and smooth cutting around field obstacles, this is the tongue design you need. It provides the ideal combination of control and exceptional maneuverability of a swivel hitch. Cut to either side or directly behind the tractor—whatever the field conditions and cutting patterns demand, the swivel gearbox maintains the PTO angle straight through the turn, extending driveline life and reliability. A new swivel hitch option available on the H7230 and H7330 allows for maximum maneuverability in the field and when transporting.

DISCBINE® DISC MOWER-CONDITIONERS Models H7220 H7320 H7230 H7330

MOWMAX™ CUTTERBAR WITH SHOCKPRO™ HUBS

Number of discs 7 7 8 8 Number of knives 14 (2 per disc) 14 (2 per disc) 16 (2 per disc) 16 (2 per disc)

Speed, rpm 3000 3000 3000 3000

Cutting width, ft. in. (mm) 9' 2" (2800) 9' 2" (2800) 10' 4" (3160) 10' 4" (3160)

Cutting angle ....2 to 10 degrees, mechanical or hydraulic control .... ..................2 to 10 degrees, hydraulic control................... Cutting height, in. (mm) ...........................................................0.95 to 3.2 (24 to 81) with standard skid shoes............................................................ Ground clearance with header 17 (432) 17 (432) 18 (457) 17 (432)

fully raised, in. (mm)

Flotation ..................................................................Vertical and lateral, adjustable springs ...................................................................

MATERIAL DISCHARGE

Swath, ft. (mm) 6 (1829) 6 (1829) 7 (2134)* 7 (2134)*

Windrow, ft. (mm) ..............Adjustable from 3 to 6 (914 to 1829) ............. ...............Adjustable from 3 to 7 (914 to 2134) ................

HYDRAULICS

Hydraulic swing .....................................................................Standard (double-acting cylinder)....................................................................... Hydraulic lift .............................................Standard (operated by two single-acting cylinders; master/slave).............................................. Hydraulic tilt .....Optional (operated by single-acting cylinder and .... ......Standard (operated by single-acting cylinder and....... incorporated into the lift system) incorporated into the lift system)

CONDITIONER

Type Chevron-design intermeshing Flail rotor with 90 tapered flails Chevron-design intermeshing Flail system with 100 tapered flails

molded rubber rolls and optional textured hood liner molded rubber or steel rolls and optional textured hood liner

Length, in. (mm) 90 (2286) 90 (2286) 102 (2591) 102 (2591)

Diameter, in. (mm) 10.4 (264) 22 (560) 10.4 (264) 22 (560)

Drive 4 HB V-belt and enclosed gears 4 HB V-belt 4 HB V-belt and enclosed gears 4 HB V-belt

Speed, rpm 647 1016 std. or optional 730 635 1000 std. or optional 718

Conditioner Adjustment Single crank adjustable roll Adjustable rotor hood with Single crank adjustable roll Adjustable rotor hood with pressure and two stop bolts to replaceable smooth liner pressure and two stop bolts to replaceable smooth liner adjust roll gap adjust roll gap

SPEEDS

Operating, mph (kph) 0 to 9 (0 to 14.5) 0 to 9 (0 to 14.5) 0 to 9 (0 to 14.5) 0 to 9 (0 to 14.5)

Transport, mph (kph) 20 (32) 20 (32) 20 (32) 20 (32)

TUBELESS AG RIB IMPLEMENT TIRES

Size 9.5L x 14 6PR 9.5L x 14 6PR 11L x 15 6PR 9.5L x 14 6PR

DIMENSIONS

Height, Transport, ft. in. (m) 5' 8" (1.7) 5' 8" (1.7) 5' 8" (1.7) 5' 8" (1.7)

Height, Operating, ft. in. (m) 4' 5" (1.3) 4' 5" (1.3) 4' 5" (1.3) 4' 5" (1.3)

Width, Transport, ft. in. (m) ............9' 11" (3.0) with standard drawbar hitch ............. ...............11' 3" (3.4) with standard drawbar hitch ................ Width, Operating, ft. in. (m) ..........14' 10" (4.52) with standard drawbar hitch ........... ...............16' 0" (4.6) with standard drawbar hitch ................ Length, Transport, ft. in. (m) ............17' 7" (5.3) with standard drawbar hitch ............. ...............17' 7" (5.3) with standard drawbar hitch ................ 19' 9" (6.0) w/swivel hitch 20' 3" (6.2) w/swivel hitch

Length, Operating, ft. in. (m) ...........17' 2" (5.2) with standard drawbar hitch ............. 17' 2" (5.2) w/std drawbar hitch 17' 8" (5.4) ) w/std drawbar hitch

19' 4" (5.9) w/swivel hitch 19' 10" (6.0) w/swivel hitch

Weight, Operating lbs. (kg) 3,690 (1674) 3,740 (1696) 4,165 (1889) 4,065 (1844)

DRIVE

Type .....540 rpm PTO, enclosed gears and four HB belt...... ..540 or 1000 rpm PTO, enclosed gears and four HB belt .. ............540 rpm PTO only for swivel hitch option.............

HITCH/TONGUE

Type ......................Side pull straight/standard...................... ......Side pull curved/standard/swivel with drawbar or ...... 2-point hookup

DRIVE PROTECTION

Type ....................................................................Slip clutch and over-running clutch .....................................................................

TRACTOR REQUIREMENT

.......65 PTO hp (48 kW)+ or greater with standard......... .......... 80 PTO hp (60 kW)+ or greater with standard............ ASAE Category II drawbar ASAE Category II drawbar

...All models require two remote hydraulic valves capable of 1500 psi (10343 kPa), 7-pin SAE J560 connector for transport lights....

TECHNICAL SPECIFICATIONS

NOTE: Rear curtain up for transport position on flail units. Windrow shields out for field and transport positions on flail and roll units.

NOTE: Minimum horsepower will not be optimum in all conditions. Add 33% to 55% more power for tough conditions.

*With the wide thin fin kit installed, swath width can be up to the full width of cut.

Models H7450 H7550 H7460 H7560

MOWMAX™ CUTTERBAR WITH SHOCKPRO™ HUBS

Number of discs 10 10 12 12

Number of knives 20 (2 per disc) 20 (2 per disc) 24 (2 per disc) 24 (2 per disc)

Speed, rpm 3000 3000 3000 3000

Cutting width, ft. in. (mm) 13 (3960) 13 (3960) 15' 7" (4795) 15' 7" (4795)

Cutting angle ...................................................................................2 to 10 degrees, hydraulic control

Cutting height, in. (mm) ........................................................................0.95 to 3.2 (24 to 81) with standard skid shoes............................................................................

Ground clearance with header 18 (457) 18 (457) 18 (457) 18 (457)

Flotation ................................................................................Vertical and lateral, adjustable springs...................................................................................

MATERIAL DISCHARGE

Swath, ft. (mm) 8 (2438)* 8 (2438)* 8 (2438)* 8 (2438)*

Windrow, ft. (mm) ................................................................................Adjustable from 3 to 8 (914 to 2438)....................................................................................

HYDRAULICS

Hydraulic swing ...................................................................................Standard (double-acting cylinder)

Hydraulic lift ..........................................................Standard (operated by two single-acting cylinders; master/slave)..............................................................

Hydraulic tilt ............................................Standard (operated by single-acting cylinder and incorporated into the lift system)................................................

CONDITIONER

Type Chevron-design intermeshing Flail system with 100 tapered flails Chevron-design intermeshing Flail system with 100 tapered flails

molded rubber or steel rolls and optional textured hood liner molded rubber or steel rolls and optional textured hood liner

Length, in. (mm) 102 (2591) 102 (2591) 102 (2591) 102 (2591)

Diameter, in. (mm) 10.4 (264) 22 (560) 10.4 (264) 22 (560)

Diameter, in. (mm) 4 HB V-belt and enclosed gears 4 HB V-belt 4 HB V-belt and enclosed gears 4 HB V-belt

Speed, rpm 740 1011 standard or optional 726 740 1000 standard or optional 726

Conditioner Adjustment Single crank adjustable roll Adjustable rotor hood with Single crank adjustable roll Adjustable rotor hood with

pressure and two stop bolts to replaceable smooth liner pressure and two stop bolts to replaceable smooth liner

adjust roll gap adjust roll gap

SPEEDS

Operating, mph (kph) 0 to 9 (0 to 14.5) 0 to 9 (0 to 14.5) 0 to 9 (0 to 14.5) 0 to 9 (0 to 14.5)

Transport, mph (kph) 20 (32) 20 (32) 20 (32) 20 (32)

TUBELESS AG RIB IMPLEMENT TIRES

Size 31 x 13.5-15 31 x 13.5-15 31 x 13.5-15 31 x 13.5-15

DIMENSIONS

Height, Transport, ft. in. (m) 6' 8" (2.6) 6' 8" (2.6) 6' 8" (2.6) 6' 8" (2.6)

Height, Operating, ft. in. (m) 5' 8" (1.7) 5' 8" (1.7) 5' 8" (1.7) 5' 8" (1.7)

Width, Transport, ft. in. (m) ...................13' 2" (4.0) with standard drawbar hitch..................... ........15' 9" (4.8) with 2-pt swivel hitch or drawbar swivel hitch .......... or 2-pt swivel hitch or drawbar swivel hitch Width, Operating, ft. in. (m) ...................19' 5" (5.9) with standard drawbar hitch..................... ..........................24' 11" (7.6) with 2-pt swivel hitch ............................ 21' 3" (6.5) with 2-pt swivel hitch 23' 3" (7.1) with drawbar swivel hitch 19' 7" (5.9) with drawbar swivel hitch

Length, Transport, ft. in. (m) ...................24' 7" (7.2) with standard drawbar hitch..................... ...........................30' 5" (9.3) with 2-pt swivel hitch

26' 5" (8.1) with 2-pt swivel hitch 29' 5 in. (8.7) with drawbar swivel hitch

25' 5" (7.4) with drawbar swivel hitch

Length, Operating, ft. in. (m) 20' 2" (5.8) w/std drawbar hitch 20' 8" (6.3) w/std drawbar hitch ...........................25' 2" (7.7) with 2-pt swivel hitch

22' 1" (6.7) w/2-pt swivel hitch 22' 7" (6.9) w/2-pt swivel hitch ........................24' 2" (7.4) with drawbar swivel hitch ..........................

21' 1" (6.1) w/drawbar swivel hitch 21' 7" (6.6) w/drawbar swivel hitch