IF WE DON'T HAVE IT ARE YOU SURE YOU NEED IT?.

CR6090 I CR7090 I CR8080 I CR8090 I CR9090

CR SERIES TWIN ROTOR® COMBINES

TAILORED HARVESTING PERFECTION

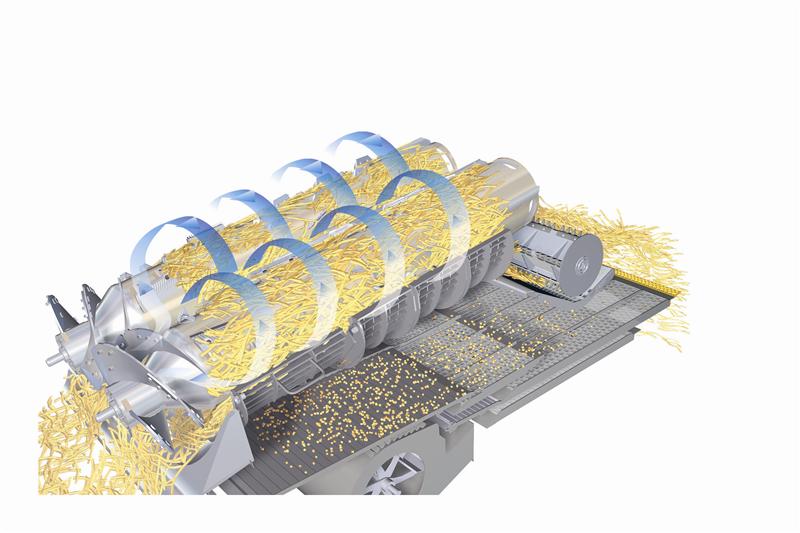

New Holland knows that in order to get the best yield in every crop flexibility is king. Therefore CR owners can choose between S3 rotors of two different diameters to suit their individual needs! The 17” on standard frame models, or opt for the 22” diameter on wide frame models, for maximum throughput for the most extensive operations. Want more? How about the 22” Twin-Pitch option? Perfect for damp harvesting conditions, where they can improve in-field performance by up to 10%. Moreover, you can customize your CR simply and easily on your farm by adjusting the rotor covers, or by changing the concaves, rasp bars, agitation pins and separating wedges for ultimate harvesting efficiency.

REVOLUTIONIZING HARVESTING FOR FOUR DECADES

REVOLUTIONIZING HARVESTING FOR FOUR DECADES

Today’s latest generation of CR Series combines continues the pure Twin Rotor® bloodline, and is the culmination of over four decades of constant evolution to guarantee best-in-class grain and straw quality, with an unparalleled 0.1% broken grain. CR combines: the default

choice for large scale harvesting excellence.

THINK GRAIN QUALITY. THINK NEW HOLLAND POWERFUL. RESPECT. FOR YOU. FOR YOUR FARM. FOR THE FUTURE.

All CR combines benefit from the productivity enhancing features of New Holland Cursor 9,10 and 13 engines equipped with ECOBlue™ SCR technology for Tier 4A compliance. These engines only breath clean fresh air for optimum efficiency and benefit from a 10% reduced cooling requirement: for example the CR9090 only requires a single rotary dust screen. What’s more, fuel consumption has been slashed by up to 9%* and you will still be able to use 5% biodiesel. Smaller fuel bills and improved productivity: more money goes in, and stays in your pocket.

*with an AdBlue®/DEF consumption of 5%.

WIDE, EVEN RESIDUE SPREADING

WIDE, EVEN RESIDUE SPREADING

To ensure consistent spreading over the full width of the widest headers, CR8080, CR8090 and the CR9090 models can be fitted with the Opti-Spread™ residue management system. Mounted behind the straw chopper the new active spreading system can cope with wider headers and uses two hydraulically driven discs and two adjustable deflectors which can be set to neutralize the impact of side-winds or hillsides, to easily meet the needs of today’s farming practices. For

total operator convenience and uninterrupted field work, the adjustments are controlled remotely from the cab.

STONE PROTECTION:THE CHOICE IS YOURS, ONLY WITH NEW HOLLAND

New Holland has introduced another industry first: a choice between two different forms of stone protection. The all-new Dynamic Stone Protection™ System uses an extra roll in the feeder housing to automatically direct stones into a dedicated trap. This system also significantly accelerates the crop for improved throughput. On-the-go harvesting is guaranteed

as the stone trap only needs to be emptied once a day. The unique Advanced Stone Protection (ASP™) System automatically detects and ejects stones to fully protect internal threshing elements with zero operator intervention.

YOUR FIELD OFFICE

Sit back, relax and enjoy harvesting in widescreen format thanks to the extra wide 10.4” IntelliView™ IV color touch screen monitor. This intuitive screen enables you to control and adjust combine functions and parameters from the comfort of your seat. The CR range’s

Harvest Suite™ cab is the largest in the industry at 110 cubic feet and offers whisper quiet operation thanks to a mere 74 dBA cab. Sit back and relax in your fully adjustable seat and keep refreshed on the hottest days courtesy of the purpose designed cooled box.

SMARTTRAX™ SYSTEM. REDUCED COMPACTION. SUPERIOR COMFORT

The 36” triangle design SmartTrax™ feature positive drive lugs to ensure maximum power is transferred to the ground, and can even lift you out of trouble in boggy fields. The rubber block suspension system guarantees operator comfort while significantly reducing

compaction, increasing traction and stability. If that wasn’t enough, SmartTrax™ guarantee tire-esque maneuverability and a transport width of 15’10”. Safety begins with a thorough understanding of the equipment. Always make sure you and your operators read the Operator’s Manual before using the equipment. Pay close attention to all safety and operating decals and never operate machinery without all shields, protective devices and structures in place.

SPECIFICATIONS

MODELS CR6090 CR7090 CR8080 CR8090 CR9090

Grain Header

Cutting width : 72C direct-cut rigid cutterbar auger ft. (m) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15)

740CF direct-cut flex cutterbar auger ft. (m) 20-35 (6.10-10.67) 20-35 (6.10-10.67) 20-35 (6.10-10.67) 20-35 (6.10-10.67) 20-35 (6.10-10.67)

760CG Varifeed™ rigid cutterbar auger ft. (m) 30 & 35 (9.15 & 10.67) 30 & 35 (9.15 & 10.67) 30 & 35 (9.15 & 10.67) 30 & 35 (9.15 & 10.67) 30 & 35 (9.15 & 10.67)

790CP windrow pickup ft. (m) 12 & 15 (3.66 & 4.57) 12 & 15 (3.66 & 4.57) 12 & 15 (3.66 & 4.57) 12 & 15 (3.66 & 4.57) 12 & 15 (3.66 & 4.57)

880CF flex cutterbar draper ft. (m) 30 - 35 (9.15 & 10.67) 30-40 (9.15-12.19) 30-45 (9.15-13.72) 30-45 (9.15-13.72) 30-45 (9.15-13.72)

92C rice draper ft. (m) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15) 25 & 30 (7.62 & 9.15)

94C grain draper ft. (m) 25-36 (7.62-10.97) 25-40 (7.62-12.19) 25-42 (7.62-12.80) 25-42 (7.62-12.80) 25-42 (7.62-12.80)

Corn Headers

98D corn head rows 6, 8 6, 8, 12 6, 8, 12 6, 8, 12, 16, 18 6, 8,12 ,16, 18

99C chopping corn head rows 6, 8 6, 8 6, 8, 12 6, 8, 12 6, 8, 12

Automatic Header Control Systems

Terrain Tracer™ system

Autofloat™ system

Straw Elevator

Number of chains 3 3 3 4 4

ASP™ system (Advanced Stone Protection)

Dynamic Stone Protection™ system - - - O O

Fixed feeder drive

Variable feeder drive O O O O O

Harvest Suite™ Cab Volume ft.3 (m³) 62.3 (5.8) 62.3 (5.8) 62.3 (5.8) 62.3 (5.8) 62.3 (5.8)

IntelliView™ IV monitor with adjustable position

ACS (Automatic Crop Settings) ô€€€

Air-conditioning and coolbox ô€€€

Automatic climate control ô€€€

MP3 radio O O O O O

New Holland Precision Land Management Systems

IntelliSteer™ ready automatic guidance system

IntelliCruise™ system O O O O O

Full precision farming package with: including:

Yield measuring and moisture measuring, D-GPS yield mapping O O O O O

Desktop software and software support service O O O O O

Twin Rotor® Technology

S³ rotors

Twin Pitch rotors - - - O O

Rotor diameter in. (mm) 17 (432) 17 (432) 17 (432) 22 (559) 22 (559)

Rotor length in. (mm) 104 (2632) 104 (2632) 104 (2632) 104 (2632) 104 (2632)

Adjustable rotor vanes O O O O O

Cleaning

Self-levelling cleaning shoe

Enhanced shake shoe cleaning system

Total sieve area under wind control in.2 (m²) 8370 (5.4) 8370 (5.4) 8370 (5.4) 10075 (6.5) 10075 (6.5)

Graintank and Unloading

Graintank manual folding extensions bushels (l) 315 (11,100) 315 (11,100) 315 (11,100) 350 (12,333) 350 (12,333)

Graintank electric folding cover bushels (l) - 326 (11,500) 326 (11,500) 355 (12,500) 355 (12,500)

Unloading speed bu/sec (l/sec) 3.7 (126) 3.7 (126) 3.7 (126) 3.7 (126) 3.7 (126)

Engine* Compliant with Tier 4 Emissions Regulations FPT Cursor 9 (8.7L)* FPT Cursor 9 (8.7L)* FPT Cursor 10 (10.7)* FPT Cursor 10 (10.7)* FPT Cursor 13 (12.7)*

ECOBlue™ SCR system (Selective Catalytic Reduction)

Gross engine power @ 2100 rpm (CV) HP 360 408 449 449 530

Maximum engine power @ 2000 rpm (CV) HP 401 449 490 490 571

Approved biodiesel blend** B5 B5 B5 B5 B5

Engine blow off system O O O O O

Fuel Tank

Diesel capacity gal. (l) 200 (750) 200 (750) 265 (1000) 265 (1000) 265 (1000)

AdBlue capacity gal. (l) 32 (120) 32 (120) 32 (120) 32 (120) 32 (120)

Transmission

Differential lock O O O O O

Road transport speed 20 mph

Road transport speed 25 mph O O O O O

Factory installed SmartTrax™ system O O O O O

Residue Management

Integrated straw chopper

PSD™ (Positive Straw Discharge) belt O O O O O

Opti-Spread™ residue management - - O O O

Weight - Standard version less header and less strawchopper lbs. (kg) 34,638 (15,712) 35,480 (16,093) 37,052 (16,807) 38,517 (17,471) 39,558 (17,943)

Dimensions with traction wheels / tracks*** 900/60 R32 900/60 R32 900/60 R32 900/60 R32 900/60 R32

Maximum width - transport ft. (m) 10' 10" (3.3) 10' 10" (3.3) 10' 10" (3.3) 10' 10" (3.3) 10' 10" (3.3)

Standard ô€€€ O Optional ô€€€ - Not available ô€€€ * Developed by FPT Industrial ô€€€ ** Biodiesel blend must fully comply with the latest fuel specification EN14214:2009 and operation is in accordance with operator

manual guidelines ô€€€ ***Traction wheels other than those mentioned are also available (800/65R32, 520/85R42 duals, 620/70R42 duals), varies with machine configurations