STRUCTURAL WOOD DECK TILES

- Certified Initiative Hardwood deck tiles- Best 5 year warranty in the business

- 22mm Gauge lumber, thickest gauge lumber possible

- Highly insect resistant and long lasting from 40-100 years

- Can be laid in continuous pattern or herringbone.

Our hardwood deck tile pavers are commercial grade in every way, yet the deck tiles perform with the luxurious beauty you would expect from a hardwood deck. Our structural hardwood pavers are made in small batches of production, creating one of the best modular deck tiles in the business. Homeowners and designers can be rest assured you wont find a better quality deck tile system. Eco Arbor has been using the same production facility for over 16 years running, creating some of the most unique certified hardwood products in the business. By using a superior quality air dried lumber, our deck tiles will last longer with a higher quality end result. Our structural deck tile system can be treated with penetrating oil sealers to enhance the natural color of the wood, or left untreated for a natural yet distinguished silver gray patina.

| Standard tile size | 23 7/8″ x 23 7/8″ (606 x 606mm) – tile dimensions 24″ x 24″ – covered area using 1/4″ spacers |

| Custom sizes | 48″ x 24″ size available on request (other sizes can be produced to order) |

| Tile height | 1 11/16″ (42mm) |

| Wood thickness | 13/16″ (21mm) |

| Slats per tile | 8 (std.) |

| Width of slats | 2 7/8″ (73mm) |

| Slat spacing | 3/16″ approx. |

| Ends & sides finish | S4S E4E (radius 1/8″) |

| Tile weight | 23.5lb. |

| Surface finish | Ends waxed with paraffin. Slats with machined finish – not coated with oil |

| Property | Specification |

| IPE | |

| Density @ 12% moisture | 1050-1180 kg/m3 |

| Durability | Class 1 (min. 25 years life) |

| Fire rating | Class A |

| Hardness (Janka) | 3680 (very hard) |

| Resistance to decay and insect attack | Resistant to attack by decay fungi and termites Not resistant to marine borers |

| Modulus of rupture | 170 MPa |

| Modulus of elasticity | 21 GPa |

| Maximum crushing strength | 94 MPa |

| Shrinkage | 7% tangential, 6% radial 1.2 tangential/radial shrinkage ratio |

| Common name | Ipe, Diamond decking, Brazilian walnut |

| Botanical name | Tabebuia sp. |

| Color | Typically reddish brown color, but can vary from olive brown to dark brown, often with lighter or darker striping |

| Grain | Fine to medium texture |

| Density @ 12% moisture | 1050-1180 kg/m3 |

| Durability | Class 1 (min. 25 years life) |

| Fire rating | Class A |

| Hardness (Janka) | 3680 (very hard) |

Structural Ipe tiles installed on a pedestal system essentially rely on our deck tile fastening system and tight spacing between the tiles and tight containment around the perimeter to keep the tiles in place without movement. The open joint space between the slats on the tiles allows wind to flow above, below and around the deck surface, which also tends to reduce uplift forces somewhat.

Since no specific standard exists regarding wind uplift of wood tiles installed on a pedestal system, Eco Arbor Designs engaged the Florida International University Hurricane Research Center to devise a test program to determine the wind speed at which uplift of our Ipe 24″ x 24″ structural Ipe tiles would occur under various conditions.

- wind angles

- pedestal heights and type

- parapet wall height

- paver layout

- locking devices along the parapet walls IE our deck tile fasteners

For each configuration, the wind speed was increased in 10 mph increments until either blow off occurred or the maximum wind speed of the Wall of Wind facility (approximately 150 mph) was reached.

The full Wall of Wind test report should be consulted for details of both the test procedure and results obtained for each set of variables, it was found that the wind speed at which blow off of the 24” x 24” structural Ipe wood tiles installed on fixed height pedestals at 0° wind angle and with a 12″ parapet was 130 mph. Note that no washer and screw assembly or any other fixing devices were used to hold down the tiles onto the pedestal heads in the tests conducted. Since this test we have developed a wood fastening system which uses a pressure fit plug into all four corners (the deck tile the deck tile connector) This plug system is now confirmed to hold the tiles down with tremendous force and meet or exceed wind uplift concerns.

INSTALLATION METHODS for Hardwood deck tiles

Hardwood deck tiles in the species Ipe, Oak, Masaranduba and similar can be used virtually over any surface.

Ground level areas the pavers can be used just like a regular stone paver and set into a sand bed. Or used over ground level concrete pads, in much the same way paving stones are laid out. The sand bed shoudl have perimeter containment and a layer of granit and sand mix of which is level. Begin placing each tile on the sand bed closely abutting each tile to the one another. Once finished wet down the area and let settle.

ON GRADE Applications on waterproof surfaces

Above living space areas such as terraces and roof decks, the pavers can be installed directly over the surface using our deck tile connectors and weather stripping tape. The tape is cut into squares and laid under the deck tile connector see photo below.

Once you have your layout of the deck configured you can begin laying your first tile. Using the deck tile connectors and plastic shims if needed the entire deck will begin to be installed very quickly. Moving from one tile to the next push the tiles down on to the corresponding plugs on the deck tile connectors. This will fasten all the tiles together creating a deck tile system that is essentially one piece. Lay all the field tiles out (any tiles not on the permimeter working row by row until every field tile is placed. Then begin installing the perimeter tiles, one by one.

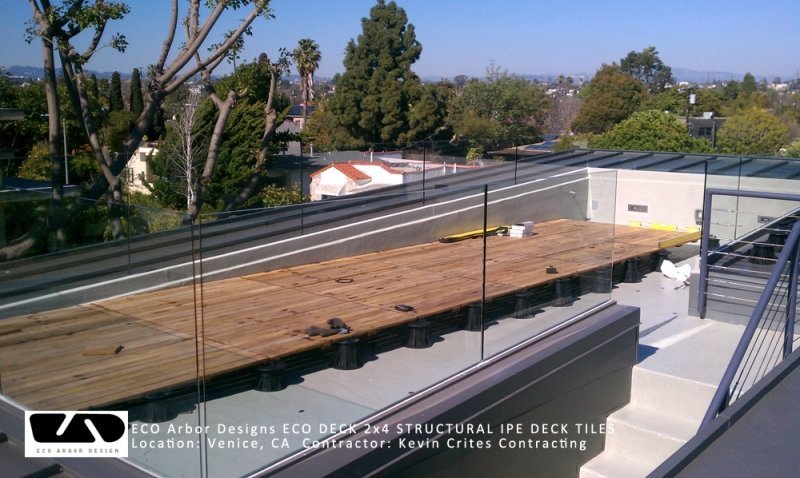

RAISED OUTDOOR FLOOR applications

Hardwood deck tiles work very well for raised floor pedestal applications. We use the Elmich adjustable pedestals as seen in photos. The reason we use the Elmich pedestal is because not only is it a very easy to use and robust system, but the wood fastening kit used on top of the pedestal is the very best fastener in the business. The fastening lock sits on top of the pedestal and allows the four corners of the tile to lock together. This creates a tight bond between each corner of the tile. You can also loosen the connector to remove tiles if necessary very easily.